Alumina catalyst support

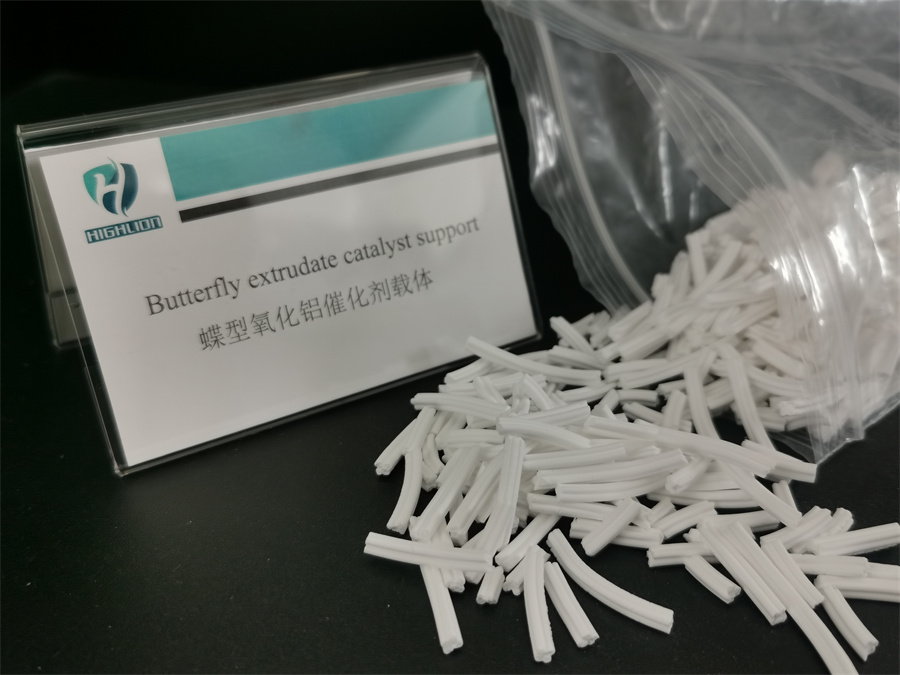

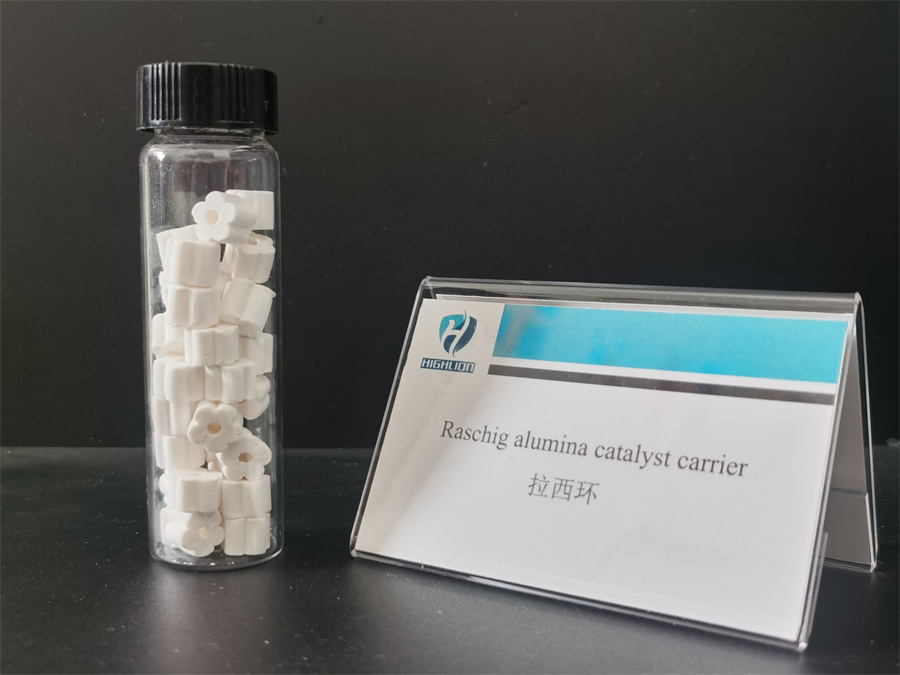

Alumina catalyst support/carrier shapes:

Trilobe shape alumina catalyst carrer

Quadrilobe shape alumina catalyst carrer

Sphere shape alumina catalyst carrier

Cylinder shape alumina catalyst carrier

Raschig ring shape alumina catalyst carrier

Gamma alumina microsphere catalyst carrier

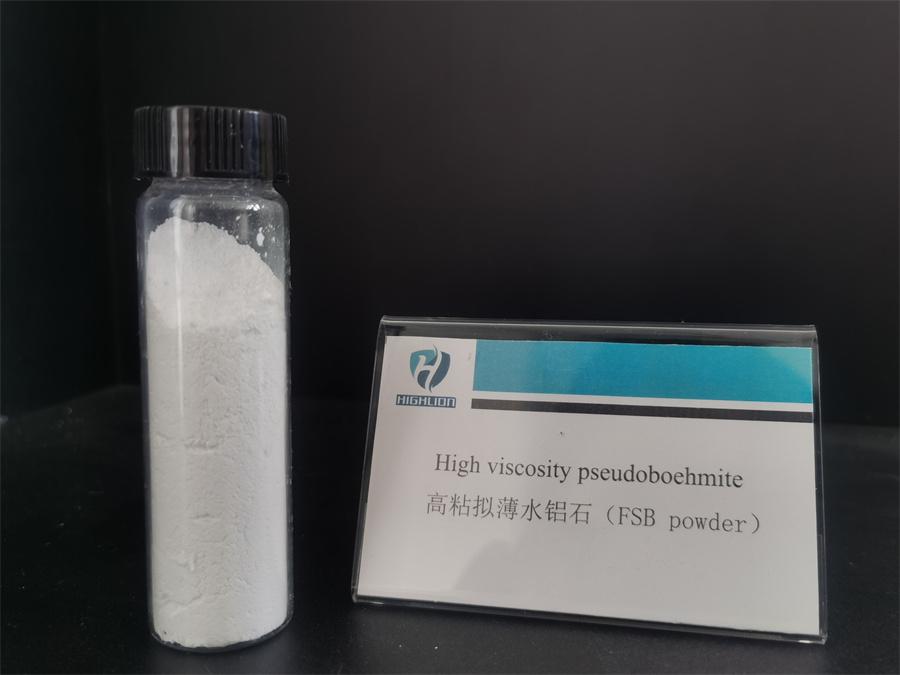

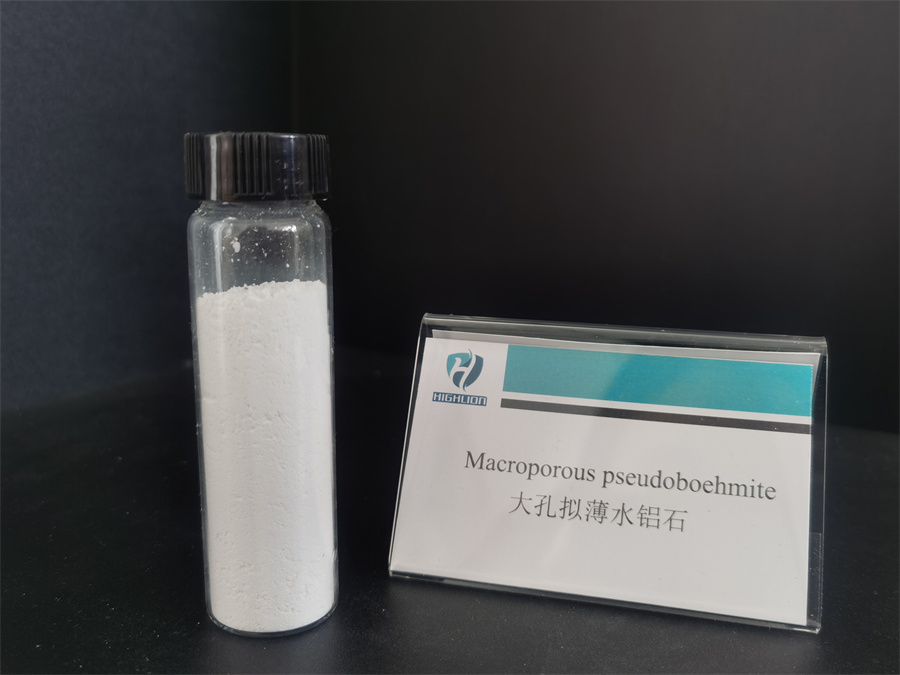

HIGHLION can produce alumina catalyst support/carrier using in different manufacturing processes mainly including extruders/extrusion,

spray dryer, tableting presses,granulators.

1. Our extruded alumina catalyst carriers including trilobe/clover/trifolium extrudates, quadrilobe/quadrifoil extrudates,butterfly extrudates,

cylinderical extrudates, rasching ring extrudates etc. The crystal form is γ-Al2O3 or θ- Al2O3.

It is used in hydrogenation catalyst series, such as gasoline and diesel hydrogenation,residual oil hydrogenation,wax oil hydrogenation,hydrocracking

diesel pour point depressant, desulfurizer, desiliconization agent, propane dehydrogenation (Lummus process) etc.

2. Our spray dryer process product is gamma alumina microspheres catalyst carrier.

Gamma alumina microsphere

Size: 75-95um

Pore volume: 0.3-0.4ml/g

Bulk density: 0.8-1.1g/ml

Specific surface are:100-350m2/g

After impregnating metal, it will be used in fluidized bed catalysts such as FCC additives,MTO catalysts.

Spherical alumina carrier

Size: 1.6-1.8mm

Pore volume: 0.5-1.0ml/g

Bulk density: 0.3-0.6g/ml

Specific surface are:100-300m2/g

It is used for propane dehydrogenation and continuous reforming.

3.Our alumina-based catalyst support with tableting presses process,after high-temperature roasting,impregnating metal,it can be used in methanation

hydrogen production catalyst etc.

4. Using our alumina catalyst carriers,HIGHLION can produce many different kinds of catalysts, they are widely used in oil refining industry and petrochemicals.